-

November 28, 2013Trends in Consumer Perceptions About Beef This Country Called Agriculture, a television show focused on agribusiness topics in Canada, recently aired...

Keep Reading -

November 27, 2013Drought Tolerant Forage Mixtures Because native species may increase carbon sequestration, improve wildlife habitat, lower agronomic inputs, and...

Keep Reading -

November 22, 2013Bigger Is Not Always Better: Finding the Right Sized Cow This is a guest post written by Karin Schmid, Beef Production Specialist with the Alberta...

Keep Reading -

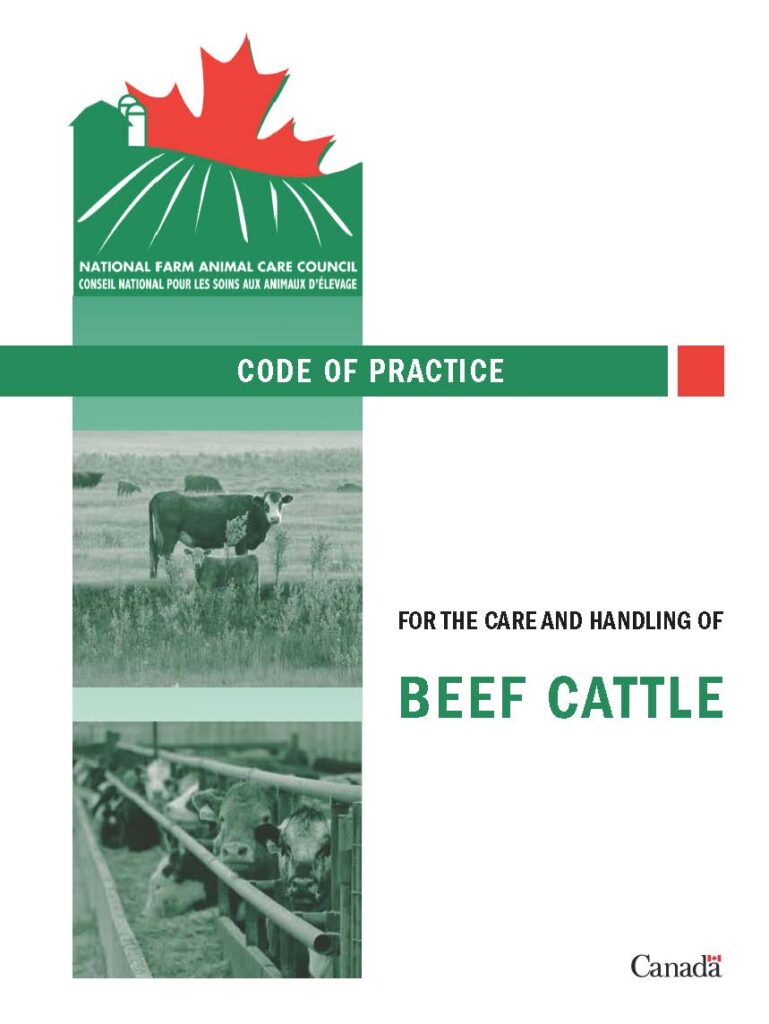

November 21, 2013Beef Research School Video: Beef Care Code Essentials in 10 Minutes In the latest episode of the Beef Research School, Ryder Lee with the Canadian...

Keep Reading -

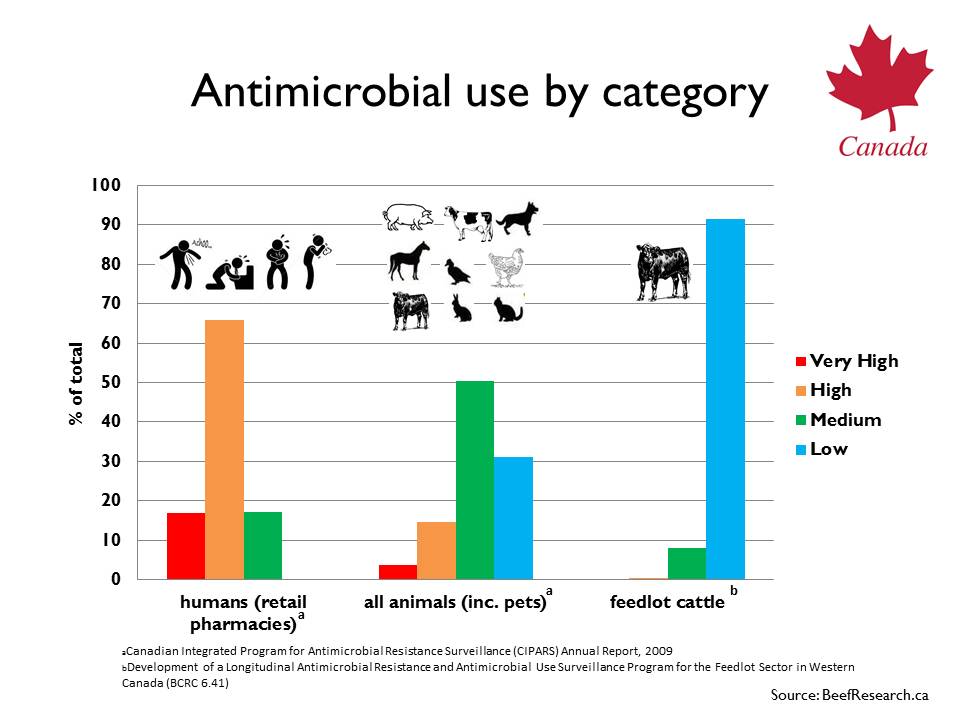

November 21, 2013Canada's Veterinary Drug Approval Process Health Canada’s Veterinary Drug Directorate1 puts all veterinary products (e.g. antimicrobials, growth...

Keep Reading -

November 18, 2013More Than One Way to Skin a Cow This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the November 2013 issue of...

Keep Reading -

November 15, 2013How to Dispose of Cattle Mortalities: New Video How best to dispose of dead cattle is an important question. Some methods are better than others at...

Keep Reading -

November 14, 2013Denmark Shows Impact of Banning Growth Promoting Antimicrobial Use in Cattle Antimicrobial resistance has become a highly charged issue. ...

Keep Reading -

November 12, 2013Raise Your Beef IQ What will tomorrow's be? Learn more about optimizing feedlot feed efficiency. Keep Reading

-

November 7, 2013Find Important Events and Deadlines Organizations across the country are continually hosting events to give you an inside look at important research...

Keep Reading -

November 4, 2013The Future of Beef Research in Canada This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the November 2013...

Keep Reading