Silage Production: Beneficial Practices for Preserving Forage Quality

Ensiling can be one of the most effective ways to preserve high-quality forage with minimal nutrient loss. When ensiled properly, the nutritive value (e.g., protein, fiber) of silage is only slightly less than fresh forage, and field losses are generally lower compared to haying. Ensiling also permits the use of a wider range of crops including grasses, legumes, grains, corn and salvage crops that have suffered weather damage or weed infestation.

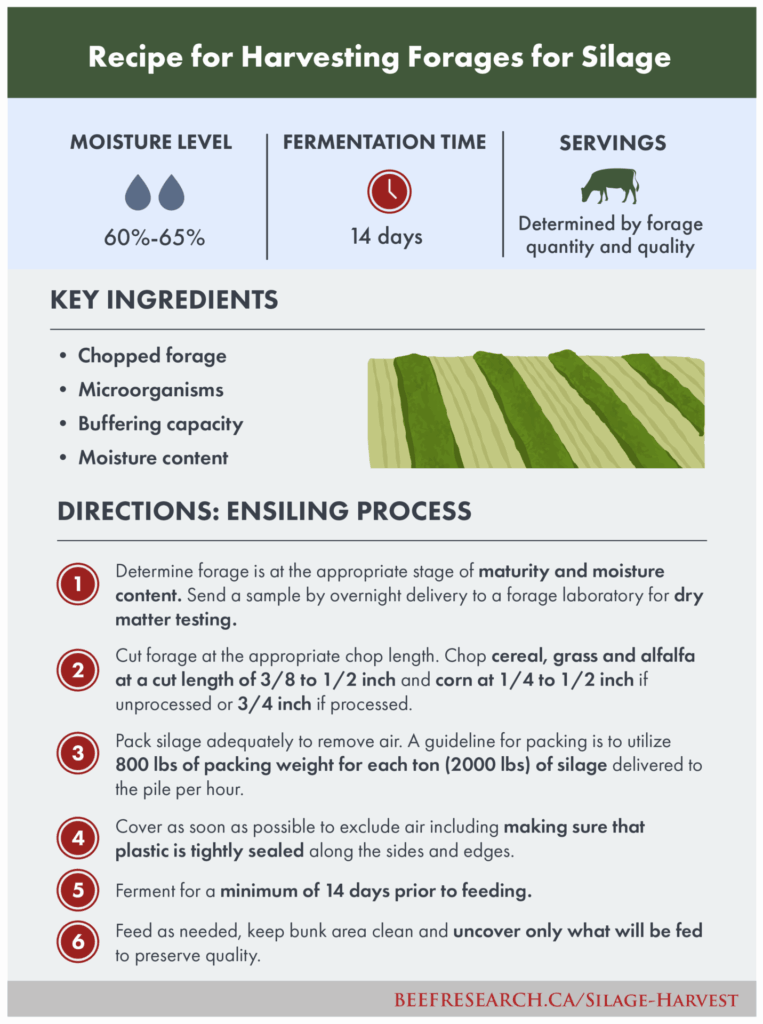

The key to silage preservation is excluding oxygen and promoting fermentation. Lactic acid-producing bacteria convert (ferment) plant sugars into lactic acid, which lowers pH and stabilizes the feed. To achieve proper fermentation, you must start with a high-quality forage crop, harvest the forage at the correct moisture, exclude air from the chopped forage as quickly as possible and tightly seal the silo, pit or bunker.

Six Key Recommendations for Silage Harvest and Management

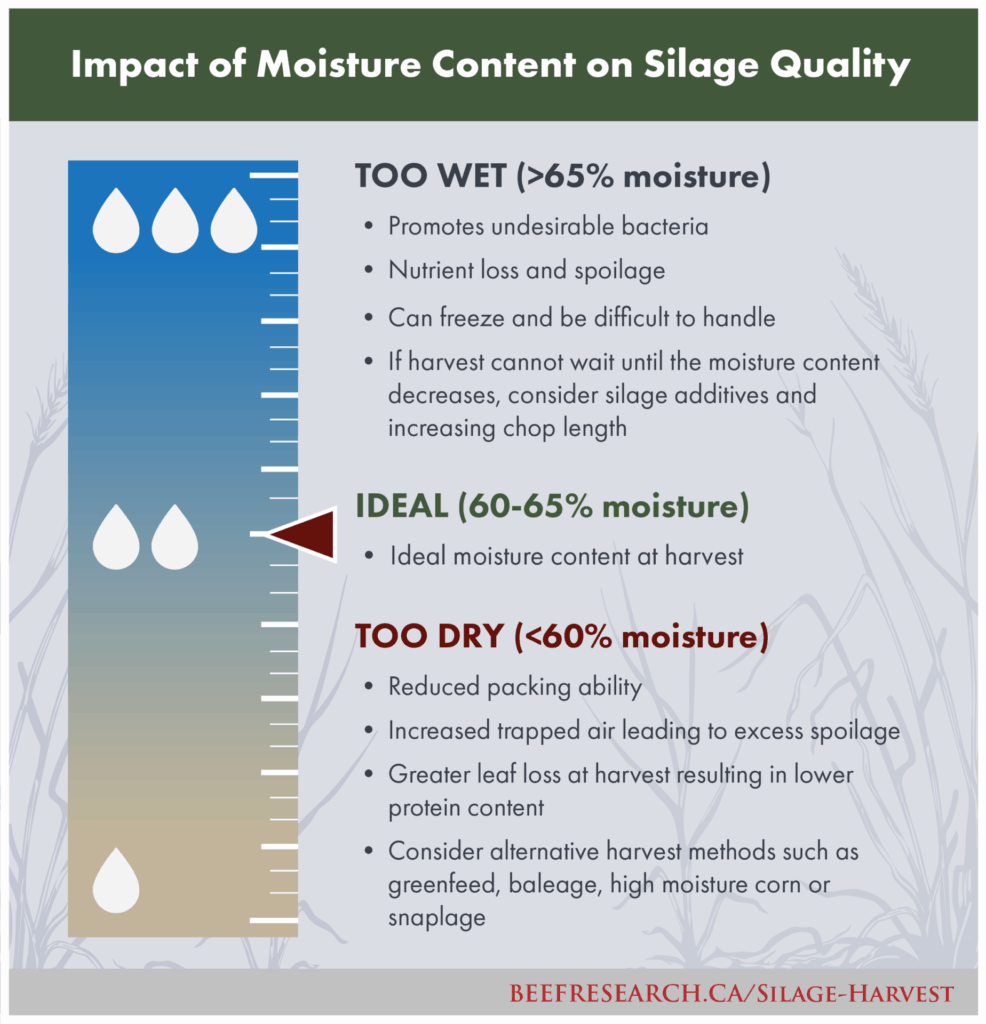

- Moisture: Aim for 60-65% moisture at harvest to increase packing effectiveness and quality. A moisture content that is too high promotes undesirable fermentation bacteria leading to nutrient loss and spoilage. If moisture is too low, the silage will not pack properly, resulting in increased trapped air leading to excess spoilage.

- Chop Length: Chop cereals, grass and alfalfa at a length of 3/8 to ½ inches and corn at ¼ to ½ inches if unprocessed or ¾ inch if processed. Shorter chop lengths pack better and reduce air pockets.

- Packing: When packing chopped forage, aim for a minimum of 40–45 lbs of fresh forage per cubic foot. A general recommendation is to use 800 lbs of packing weight per ton delivered per hour. Each packing layer should be no more than 6 inches thick.

- Sealing: Cover silage immediately with airtight plastic and secure with tires or other weights. Seal edges tightly to prevent air infiltration.

- Time: Seal for a minimum of 14 days. This allows sufficient time for the ensiling process to complete.

- Feed Out: An average daily removal rate of 15-20 cm from the silage feed-out “face” (the smooth surface perpendicular to the floor and sides in bunker or pit silage storage) is a common recommendation. To achieve this, the amount of silage to meet daily feeding requirements is used to calculate the size and face of your silage pile or pit.

What About Silage Additives?

Silage additives can be used to improve fermentation, reduce storage losses and enhance the feed’s nutritional value. However, they are not a replacement for good management.

There are two main categories of silage additives:

- Fermentation inhibitors, like propionic acid, suppress the growth of undesirable microbes which helps to prevent spoilage during storage and feed out.

- Fermentation stimulants, like bacterial inoculants and enzymes, speed up lactic acid production and enhance fermentation.

Prior to using an additive, it is necessary to weigh the cost against the potential improvements in feed quality and cattle performance. Always follow label directions.

Making Quality Silage for Beef Cattle

Weather and management play a big role in silage quality, but, focusing on a few key steps during harvest can make a significant difference. Harvest at the proper moisture level, ensure thorough packing and sealing, and manage feed-out carefully. With these good practices, silage can become a dependable, high-quality feed choice for beef cattle producers.

Sharing or reprinting BCRC posts is welcome and encouraged. Please credit the Beef Cattle Research Council, provide the website address, www.BeefResearch.ca, and let us know you have chosen to share the article by emailing us at [email protected].

The BCRC is funded by a portion of the Canadian Beef Cattle Check-Off.

Your questions, comments and suggestions are welcome. Contact us directly or spark a public discussion by posting your thoughts below.