-

January 25, 2024BCRC Funds Proof of Concept and Technology Transfer Projects to Propel Canadian Beef Industry Forward Six POC research projects and 13 KTT activities...

Keep Reading -

December 12, 2023The Results Are In on 2018-2023 Beef Cluster Projects Summaries of recent beef and forage research results funded by the Canadian Beef Cattle...

Keep Reading -

May 30, 2023A Quarter-Century of Research Advances in Tackling E. coli The past 25 years of research and improved sanitation practices have caused a significant...

Keep Reading -

January 16, 2023The BCRC Celebrates 25 Years of Beef Industry Research 2023 marks 25 years for the BCRC as Canada’s national industry-led funding agency for beef,...

Keep Reading -

August 10, 2022Getting the Dirt on Cleaning Versus Disinfecting 🎙️ Clean and disinfect against pathogens entering and spreading through your animals, saving...

Keep Reading -

December 14, 2020Are E. coli Really Becoming More Heat Resistant? This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the...

Keep Reading -

November 19, 2020Do Cattle Bacteria Contribute to Antibiotic Resistance in Human Medicine? This article written by Dr. Reynold Bergen, BCRC Science Director,...

Keep Reading -

November 19, 2018Your Burgers Are Still Done at 71 This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the November 2018 issue of...

Keep Reading -

October 5, 2018Developing Faster, Less Expensive Diagnostic Tests This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the...

Keep Reading -

November 21, 2016Non-O157 STEC This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the November 2016 issue of Canadian Cattlemen...

Keep Reading -

April 18, 2016Dry Chilling (and two other things) This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the April 2016 issue of...

Keep Reading -

August 28, 2015Consumer MisReports Consumer Reports Food Safety and Sustainability Center released its “Beef Report” on August 25. A number of questions,...

Keep Reading -

March 16, 2015Hot Water Treatment of Beef Trim This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the March 2015 issue of...

Keep Reading -

November 24, 2014Practical and Effective Food Safety Procedures for Beef Packing Plants Recent work has shown that E. coli can essentially be eliminated from dressed...

Keep Reading -

October 21, 2014Flipping for Mechanically Tenderized Beef This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the October 2014...

Keep Reading -

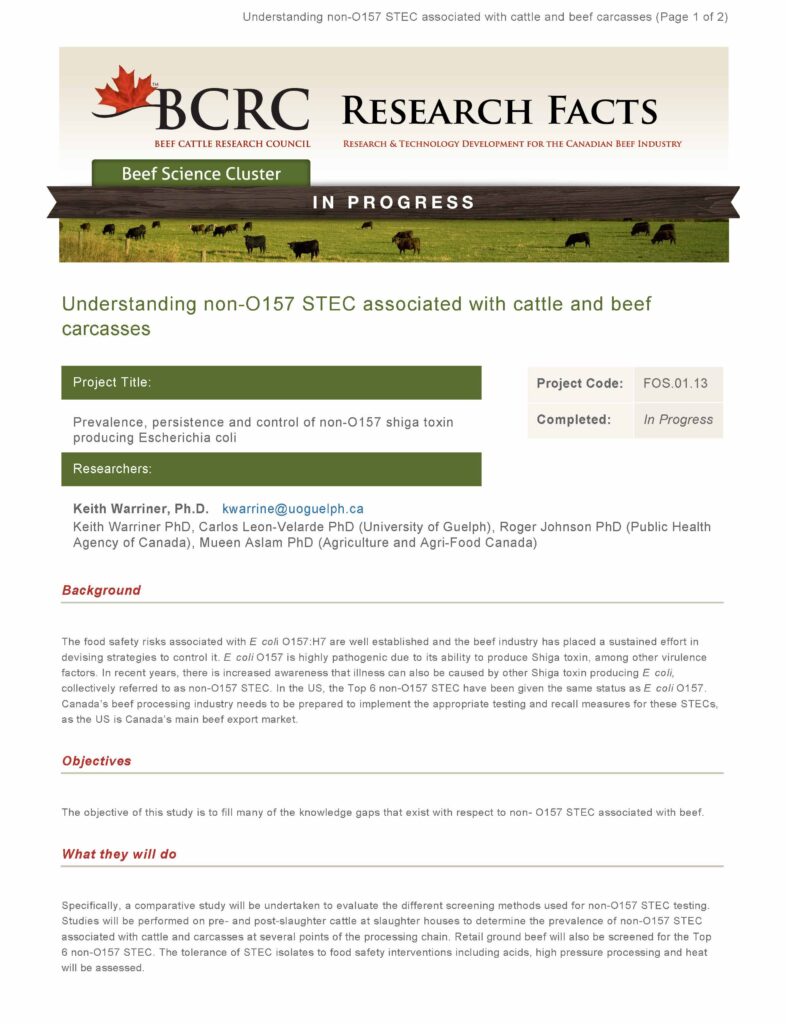

September 12, 2014Understanding Non-0157 STEC Associated with Cattle and Beef Carcasses The food safety risks associated with E. coli O157:H7 are well established and...

Keep Reading -

February 18, 2014Beam Me Up This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the February 2014 issue of Canadian Cattlemen...

Keep Reading -

January 17, 2014Bug Spray for Beef? This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the January 2014 issue of Canadian...

Keep Reading -

December 16, 2013Better Housekeeping This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the December 2013 issue of Canadian...

Keep Reading -

November 18, 2013More Than One Way to Skin a Cow This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the November 2013 issue of...

Keep Reading -

June 7, 2013On-farm E. coli O157:H7 Control? Editor's note: Following the recent release of the Independent Review of XL Foods Inc. Beef Recall 2012, we thought...

Keep Reading -

May 24, 2013How do Carcass Processing Procedures Impact Food Safety? Canadian beef packing plants have progressively and effectively modified their processes over...

Keep Reading -

May 21, 2013E-beam Irradiation Research: New Fact Sheet and Video Irradiation is approved for food treatment in over 50 countries. In Canada, irradiation is...

Keep Reading -

April 29, 2013Revisiting Irradiation This article written by Dr. Reynold Bergen, BCRC Science Director, originally appeared in the January 2013 issue of Canadian...

Keep Reading -

February 11, 2013Food Safety Research on Mechanically Tenderized Beef This is a guest post written by Mark Klassen, Director of Technical Services for the Canadian...

Keep Reading -

November 5, 2012Latest Results from Antimicrobial Resistance Surveillance The Public Health Agency of Canada has completed its most recent report on the Canadian...

Keep Reading -

October 5, 2012E. coli O157:H7: an Industry Research Priority E. coli O157:H7, the cause for the recent, extensive beef recall, is one of the few types of E. coli...

Keep Reading