The Canadian beef industry has made significant improvements to feed efficiency, management and genetics over the years. However, there is still room for improvement1,2, including the increased adoption of underutilized technologies proven to yield high returns with conservative inputs. One example of a safe, cost-effective and low-input technology is growth-promoting implants.

Despite being around for decades and used by almost all feedlot operations in Canada, only a quarter of cow-calf operators implant suckling calves, potentially sacrificing 20% of weaning weight. A large portion of these cow-calf producers feel they lack knowledge and confidence about implants and how to give them. This resource serves as your guide to implanting and how it can benefit your operation.

| Key Points |

|---|

| The safety and effectiveness of growth implants in pre- and post-weaned calves has been demonstrated multiple times over the last 50 years. |

| Growth implants require no withdrawal time as ears are always removed at the time of processing and never enter the food system. |

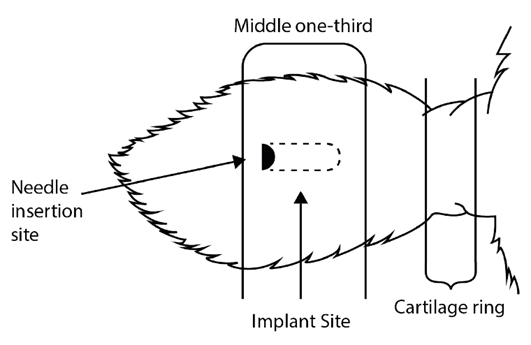

| The only approved location for hormone growth implants in beef cattle is under the skin, above the cartilage, in the middle one-third of the back of the ear. |

| Best Practices for Hormone Implants – Always follow label instructions for proper storage and administration. – Ensure your needles, the calf’s ear, and your hands are clean. – Clean and disinfect needles between each implant. – To avoid abscesses, try to implant on days and in areas where the ground is clear and dry. – Properly restrain the animal to ensure appropriate implantation and reduce potential harm to the animal and handler. – Do not implant at birth. – Avoid ear tags, ear tag holes, or where the ear tags will be placed. – Slow down – Implanting is not a race. Ensuring implants are deposited correctly is essential to maximize productivity, animal health and welfare, and human safety. |

| Proper sanitation prior to and during implanting is often overlooked. Improper sanitation can have serious implications, including infections and abscesses that can reduce performance and the effectiveness of the implant. |

| Implanting calves at spring processing does not affect beef quality. |

Overview

Growth implants are small pellets containing synthetic or natural hormones that are implanted under the skin of the back of the animal’s ear. The hormone releases slowly over 100 to 120 days and economically increases growth rates and efficiency. There is no withdrawal time as ears are always removed at the time of processing and never enter the food system. Implants are one of the most cost-effective technologies available across the Canadian beef industry from cow-calf to backgrounding through to finishing. Though implants are commonly used in backgrounding and feedlot cattle, they are less common in the cow-calf sector despite similar performance and economic benefits.

- What are the economic benefits?

- What equipment do I need?

- How do I administer implants to ensure calf safety, human safety and effective implantation?

- What benefit do implants have for cattle?

Science has demonstrated the safety and efficacy of growth implant use in pre- and post-weaned calves for over 50 years.3 Canadian cow-calf producers can use growth implants to enhance growth rates and feed efficiency in pre-weaned calves. Studies suggest that implanting at this stage can result in a 3% to 18% improvement in average daily gain compared to non-implanted calves.3,4,5,6,7,8,9,10 Implants improve growth in both steers and heifers, although, as seen naturally, heifers will still grow more slowly than steers of the same age, breed and timing of implant.11 This improved growth efficiency translates to calves being 15 to 40lbs heavier at weaning compared to non-implanted calves generating $20 to $40 more per calf at sale, while the typical implant only costs $1.50/hd.4,12,13

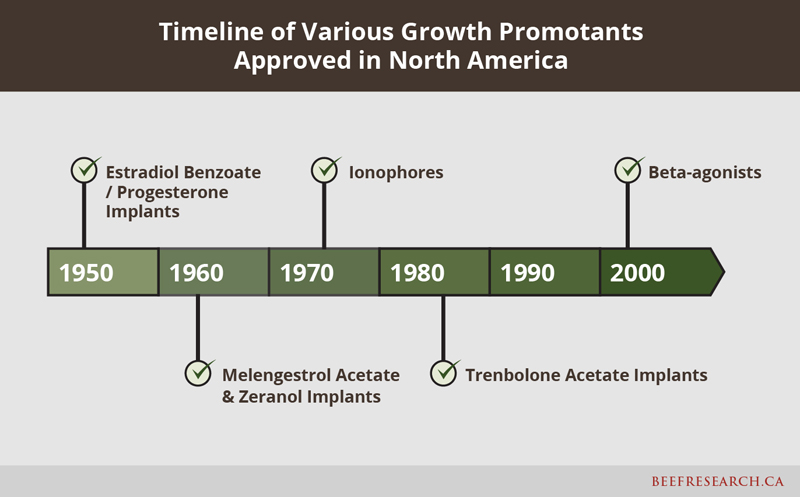

Current Implant Use

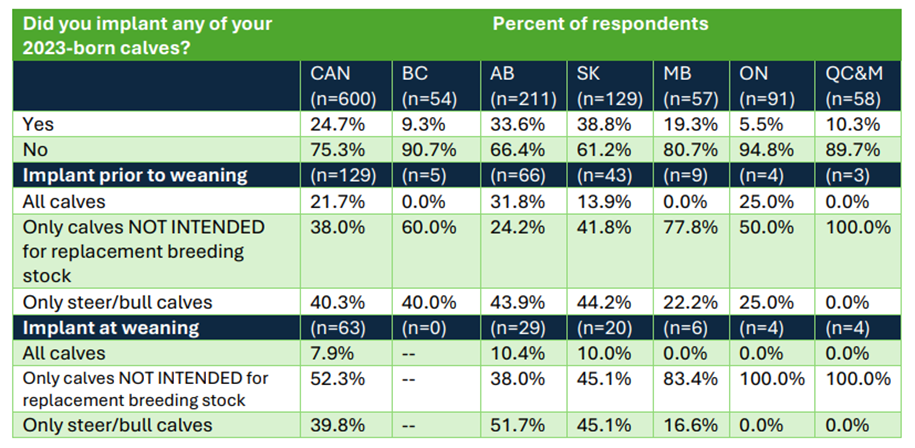

According to the 2022-2023 Canadian Cow-Calf Survey (CCCS)14, 24.7% of respondents implanted their 2023-born calves. However, there is regional variation, with implantation rate at the cow-calf level being as low as 5.5% in Ontario and as high as 38.8% in Saskatchewan. Recent survey studies break this down further: of the producers implanting, 21.5% to 31.0% of respondents report they implant suckling calves while 10.5% to 18.0% report implanting at weaning.14,15

Table 1. 2022-2023 Canadian Cow-Calf Survey results (BCRC 2024).

What Do I Need To Get Started with Implants?

Before implanting can be adopted into a herd’s management system, inventory of existing equipment, facilities and labour access must be conducted to ensure producers are prepared to safely and effectively implant calves.

Requirements:

- Proper chutes or restraint: This can include a chute with a headgate, tipping tables, Nordforks, roping or proper physical restraint. The more controlled the restraint the better to ensure proper implantation and animal and human safety.

- Implants: There are four implants approved for use in suckling calves: Ralgro (Merck), Synovex-C (Zoetis), Compudose (Elanco) and Component E-C (Elanco). Talk to your veterinarians about which is the best fit for your operation. Product labels are available at the Compendium of Veterinary Products.

- Implant gun: Each type of implant has its own specialized applicator or implant gun and is not interchangeable. Be sure to use the right one.

- Replacement needles: Sterile needles should be on hand to change routinely or after they have become dull or damaged.

- Sharps container: A container for disposing of used needles.

- Sponge or roller: These are used to clean needles between every implant. Sponges or rollers soaked in a chlorohexidine solution will remove physical debris and disinfect the needle. Needles also can be dipped directly into the disinfectant solution though sponges, and rollers are recommended to more effectively remove physical debris.

- Brush: Have a brush on hand to clean dirty ears before implanting.

- Clean workstation: Wherever implantation is taking place, ensure there is a clean area where disinfectant, sponges, implant guns and sterile needles and implants can be stored.

Video: To Implant or Not? What Cow Calf Producers Need to Know

Proper Implant Use

For suckling beef calves, Ralgro® and Synovex® C are recommended hormone implants, though there are other implants available for calves weighing less than 400lbs11 (Table 2). Each implant will have a specific applicator, commonly called an implant gun, that is required to safely and effectively administer the implant. For best use, follow the label directions of your implant of choice. Most implants are recommended to be administered between two months and four months of age. However, calves should be at least 30 days (Ralgro®) and 45 days (Synovex®-C) of age. This timing makes branding an appropriate and convenient time to implant calves.

Implants designed for use in suckling calves release the hormone over a period of 100 to 120 days, although studies report carryover effects (growth advantages in a subsequent phase of feeding from the implant in the previous phase) from weaning to 60 days10 and even up to carcass weight.8 However, other studies suggest this carryover effect is not significant.16,17

Table 2. Beef cattle implants approved for use in suckling calves less than 400 pounds (adapted from Beck et al. 2022).

| Steer | Heifer | Implant | Company | Ingredient/Dose | Relative Potency | Payout |

|---|---|---|---|---|---|---|

| x | x | Ralgro | Merck | 36 g zeranol | Low | 70 to 100 days |

| x | Compudose | Elanco | 25.7 mg estradiol | Moderate | 170 to 200 days | |

| x | x | Synovex C | Zoetis | 100mg progesterone 10mg estradiol benzoate | Low | 70 to 100 days |

| x | x | Component E-C w/ Tylan | Elanco | 100mg progesterone 10mg estradiol benzoate 29mg tylosin tartrate | Low | 100 to 140 days |

| x | x | Component E-C | Elanco | 100mg progesterone 10mg estradiol | Low | 100 to 140 days |

Implants are designed with management in mind. Therefore, as calves move from being at their dam’s side to being weaned and onto a new diet, the implants used will increase in potency and hormone proportions shift.

Table 3. Implants approved for backgrounding growing beef calves in Canada.

| Steers, Heifers, Both | Management | Implant | Company | Ingredient/Dose | Relative Potency | Payout |

|---|---|---|---|---|---|---|

| Both | Grassers and stockers | Revalor-G | Merck | 40mg trenbolone acetate 8mg estradiol | Moderate | 150 days |

| Both | Stockers | Revalor-100 | Merck | 100mg trenbolone acetate 10mg estradiol | Moderate | 50 to 90 days |

| Heifers | Grassers and stockers | Synovex H | Zoetis | 200mg testosterone propionate 20mg estradiol benzoate | Moderate | 70 to 100 days |

| Steers | Grassers and stockers | Synovex S | Zoetis | 200mg progesterone 20mg estradiol benzoate | Moderate | 70 to 100 days |

| Both | Grassers and stockers | Synovex Primer | Zoeitis | 50mg trenbolone acetate 7mg estradiol | Moderate | 70 to 100 |

| Steers | Grassers and stockers | Compudose | Elanco | 25.7mg estradiol | Moderate | 200 days |

| Both | Grassers and stockers | Component TE-G | Elanco | 40mg trenbolone acetate 8mg estradiol | Moderate | 100 to 140 days |

| Both | Grassers and Stockers | Synovex One Grower | Zoetis | 150mg trenbolone acetate 21mg estradiol benzoate | Moderate | 200 days |

| Both | Grassers and stockers | Synovex Primer | Zoetis | 50mg trenbolone acetate 7mg estradiol benzoate | Moderate | 200 days |

| Both | Grassers and stockers | Synovex Choice | Zoetis | 100mg trenbolone acetate 14mg estradiol benzoate | Moderate | 200 days |

| Both | Grassers and stockers | Component TE-G w/ Tylan | Elanco | 40mg trenbolone acetate 8mg estradiol 29mg Tylosin tartrate | Moderate | 100 to 140 days |

| Both | Grassers and stockers | Ralgro | Merck | 36 g zeranol | Low | 70 to 100 days |

Implant Location

The only approved location for growth implants in beef cattle is subcutaneous (under the skin and above the cartilage) in the middle one-third of the back of the ear.

Figure 1: Only approved and correct location for growth implants Beck et al. 2022

How to Use Growth Implants in Cattle

- Always follow label instructions regarding proper storage and administration.

- Ensure the needles, calf’s ear and your hands are clean.

- Clean needles between each implant.

- Avoid abscesses by implanting on days and in areas where the ground is clear and dry.

- Properly restrain the animal to ensure proper implantation and reduce potential harm to the animal and handler.

- Do not implant at birth.

- Avoid ear tags, ear tag holes or where ear tags will be placed.

- SLOW DOWN – implanting is not a race. Ensuring implants are deposited correctly is important to maximize productivity, animal health and welfare and human safety.

11 Steps to Implantation

1. Prepare before you begin11.

- Read the label instructions of the chosen implant and applicator.

- Acquire the products needed for sanitation.

- Make sure you are familiar and confident using the implanting applicator.

- Load the gun and place it in the disinfectant tray.

2. Properly restrain the calf.

3. Inspect the ear.

- Make sure there is not already an implant.

- Check for abscesses and ear tag holes.

- Ensure the surface is clean and free from dirt or manure.

4. Wipe or clean soiled hands before handling the applicator. Mud, dirt, manure or blood can impact the inner workings of the applicator and cause issues later.

5. Wipe the needle through the sponge to disinfect it. Pull the tips of the needle across the sponge (bevel facing down towards the sponge’s surface) to clean out any material that may be inside.

6. Pinch the top of the calf’s ear with your index finger and thumb. Place the top of the applicator needle against the ear on a slight angle, bevel side up (away from the ear) on the outer edge of the implant zone.

7. Insert the needle at a flat angle and slide it all the way into the ear, between the skin and hard cartilage. Avoid puncturing the cartilage. Should the needle puncture cartilage or go through the ear, return to step 5 to avoid implanting the biological material with the implant in the next attempt.

8. Slide the needle back out of the ear (about the length of the implant). Some applicators will do this automatically so be aware of the workings of the equipment.

9. Pull the trigger to deposit the implant, then withdraw the needle completely.

10. Feel the implant site to ensure the pellet is properly inserted. Ensure it is not bunched up or crushed. If it is, slide the needle out a bit farther (step 7) on the next calf.

11. Clean the needle by dipping into the chlorohexidine solution or wiping with a sponge or roller soaked in the solution after every implant

Proper Sanitation When Implanting

Sanitation is probably the most overlooked step that can have serious implications for health and welfare of the animals being implanted. Improper sanitation of equipment, ear and workspace can result in infections and abscesses that not only cause pain and increased production costs to account for treatment, but also reduce the effectiveness of the implant itself.

Take these steps to ensure proper sanitation during while implanting:

- Use clean equipment. Store implants, guns, sponges and rollers in a clean area, and keep them clean and free from dirt, manure and other debris.

- Use clean hands. Thoroughly wash hands before implanting and when hands get soiled with dirt, manure, blood, etc. Using hand sanitizer between calves also prevents risk of infection.

- Replace needles when noticeably dull or damaged.

- Disinfect needles in a premixed 2% chlorohexidine solution or wipe with a sponge or roller soaked in the solution between implants.

- Keep the needle sterile. Avoid contact with any non-sterile surfaces after the needle has been disinfected.

- Replace the disinfectant solution when it appears cloudy or between each group of calves.

Sanitation is the best way to prevent infection and abscesses. Some implants contain an antibiotic intended to reduce the incidence of abscesses. This may be something worth considering for producers who have had problems with abscesses in the past, in addition to looking at implanting procedure and enhanced sanitation protocol.

Management and Marketing Considerations

Implanting a suckling calf will not negatively impact feedlot performance, animal behaviour or carcass quality, provided a calf implant is used. Suckling calves do not benefit from the more costly, more potent implants designed for backgrounding or feedlot cattle. If producers are retaining their calves post weaning for backgrounding or finishing or both, implant management will be dependent on the way that the cattle will be marketed.

Marketing Considerations Before Implanting Calves:

- Feed cost

- Value of additional weaning weight

- If there is potential to capture a premium by marketing non-implement calves

Management Considerations

General: Proper timing (age of calf) and placement are VITAL. Follow label directions. Do not implant calves at birth. Do not use implants in dairy cattle or veal calves.

Steers: May increase incidence of mounting of other steers or standing to be mounted, also known as bulling (or bullers).

Bull calves: Never implant bull calves that will be or might be kept for breeding. Castrate at the time of implanting. Implants can cause the scrotal development to be inhibited, which can result in more difficulty castrating as the animal ages. If you intend to retain a calf as a bull, NEVER implant.

Heifers: Despite concerns, heifers that are or could potentially be replacement animals can be safely implanted with no significant impact on conception rate or calving ease, as long as they are only implanted once within the timeframe recommended by label (typically at least 45 days) and never post-weaning, although implanting at weaning is fine.18,19

Heifers that are implanted at birth, multiple times before weaning or after weaning have had significantly lower conception rates compared to non-implanted heifers and heifers only implanted once before weaning.18 Implants given at the wrong time or too often can cause signs of estrus, vaginal or rectal prolapses, udder problems or other reproduction issues.

Where to Start

You know the steps, the hows and the whys but aren’t sure about starting a full implant program on all calves next year? That is ok. Better to start small and then expand than to take on more all at once. There are a few options you can consider when approaching your first-year implanting:

Option 1: Only implanting a portion of the herd to compare success

- Implanting a percentage of your spring processed calf crop not only allows you to try a new practice slowly without pressure and with room to learn and grow, but also allows direct comparison of performance between implanted calves and non-implanted calves raised under the exact same conditions.

- If applying this method, starting weights and weaning weights of both groups (implanted and non-implanted) are valuable to draw meaningful conclusions.

- If using both heifers and steers, make sure the proportion of gender is similar in both to implanted and non-implanted groups for consistency, given the likely differences between genders and that heifers have a slower growth response to implants compared to steers of the same age and breed.

Option 2: Only implanting steers

There is hesitancy by producers to implant heifers intended to be used as replacements, due to concerns about reproductive impacts. Though it is safe to implant replacement heifers once prior to weaning, only implanting steers addresses these concerns while still benefitting from the added growth potential in the steer crop.

Impacts of Implants on Beef Quality

While implants offer notable production advantages, they have been shown to reduce carcass qualities such as marbling and tenderness. Significant impacts to meat quality are typically associated with aggressive hormone programs at the feedlot level and can be mitigated by responsible management.20 While research indicates that implanting suckling calves has no negative impact on subsequent performance or carcass quality, it is still an important consideration when planning a hormone program on farm.6,8 Especially if calves will be retained for backgrounding or to slaughter, ensure the hormone program is on an increasing plane of strength.

Overall, hormones tend to reduce intramuscular fat (marbling), a key determinant of meat quality grades. Research indicates that implanted cattle are 5-8% leaner than non-implanted cattle at any stage of the feeding period or production cycle.21 However, the additional gain captured by hormones for a producer selling animals based on weight can still result in a higher income per head and offset lost opportunity costs.22

Hormones’ impact on tenderness is more nuanced. While studies report decreased tenderness through shear force tests as a direct result of hormone implants, the effect could not be discerned by the sensory panel.23

- References

-

1. Beef Cattle Research Council. (2021). Five-Year Canadian Beef Research and Technology Transfer Strategy.

2. Canadian Cattle Association. (2022). Canadian Beef Industry Goals 2030.

3. Mader, T. (1997). Implants. American Association of Bovine Practitioners Conference Proceedings.

4. Bagley, C.P., Morrison, D.G., Feazel, J., Saxton, A. (1989). Growth and sexual characteristics of suckling beef calves as influenced by age at castration and growth implants. Journal of Animal Science. 67(5):1258-1264.

5. Mader, T. (1998). Veterinary Clinic of North America: Food Animal Practice. 14(2):279-290.

6. Duckett, S., Andrae, J. (2001). Implant strategies in an integrated beef production system. Journal of Animal Science. 79(SupplE): 110-117

7. Stewart, L. (2010). Implanting beef cattle. https://hdl.handle.net/10724/11988

8. Pritchard R., Taylor, A., Holt, S., Bruns, K., Blalock, H. (2015). Time of suckling implant influences on weaning weight, post-weaning performance, and carcass traits in steers. South Dakota State University.

9. Reinhardt A., and Thompson, D. (2016). Growth promotant implants in suckling calves and stocker cattle. Bovine Practitioner 50(1):40-46. 10.21423/bovine-vol50no1p40-46.

10. Lasso-Ramirez, S., Medeiros da Silva, G., Moya, D., Lardner, H., Londono-Mendez, M.C. (2024). Using growth implants in suckling beef calves enhanced vaccine response against Infectious Bovine Rhinotracheitis. Journal of Animal Science. 102:170-171. https://doi.org/10.1093/jas/skae234.197

11. Beck, P., Reuter, R., Lalman, D. (2022). Implants and their use in beef cattle production. Oklahoma State University Extension.

12. University of Nebraska-Lincoln, UNL Beef. (2020). Implants in nursing calves.

13. Manitoba Beef and Forage Institute. (2024). Demonstration Study at Brookdale Farm.

14. Beef Cattle Research Council. (2024). 2022-23 Canadian Cow-Calf Survey Summary Report. Calgary, AB: Canfax Research Services.

15. Lazurko, M.M, Erickson, N.E.N., Campbell, J.R., Larson, K., Waldner, C.L. (2024). Technology adoption and management practices used in Canadian cow-calf herds. Canadian Journal of Animal Science 104(4): 524-539. https://doi.org/10.1139/cjas-2023-0080

16. Reuter R.R., and Beck, P.A. (2013). Southern Section Interdisciplinary Beef Symposium: Carryover effects of stocker cattle systems on feedlot performance and carcass characteristics. Journal of Animal Science. 91:508.

17. Webb M.J., Harty, A.A., Salverson, R.R., Kincheloe, J.J., Zuelly, S.M.S., Underwood, K.R., Luebbe, M.K., Olson, K.C., Blair, A.D. (2017). Effect of nursing-calf implant timing on growth performance and carcass characteristics. 95(12): 5388-5396.

18. Selk, G. (1997). Implants for suckling steer and heifer calves and potential replacement heifers. In Symposium: Impact of implants on performance and carcass value of beef cattle (pp. 40-50). Stillwater: Oklahoma Agricultural Experiment Station.

19. Rasasco, S., Schmitz, L.H., Cox, S.H., Dunlap, R.C., Hallford, D.M., Summers, A.F., Scholljegerdes, E.J. (2018). Effects of growth-promoting implants administered during the suckling phase on growth, conception rates, and longevity in replacement beef heifers grazing native range. Transatlantic Animal Science: S180-S184.

20. Barham, B., Beck P., Gadberry, S., Apple, J., Whitworth, W., Miller, M. (2012). Effect of age entering the feedlot and implant potency on animal performance, carcass quality, and consumer acceptance of beef. The Professional Animal Scientist. 28:30-31.

21. Hamlyn-Hill, F. (2019). Hormonal Growth Promotants (HGPs): growth and carcass responses. Future Beef.

22. Gonzalez, P, Draughon, B. (2024). The Pros and Cons of Implementing Beef Calves: A Tool for Performance and Profit. North Carolina State University Cooperative Extension.

23. Lean, I.J., Golder, H.M., Lees, N.M., McGilchrist, P., Santos, J.E.P. (2018). Effects of hormonal growth promotants on beef quality: a meta-analysis. Journal of Animal Science. 96(7):2675-2697.

Feedback

Feedback and questions on the content of this page are welcome. Please e-mail us.

This content was last reviewed September 2025.