Fencing & Water Infrastructure on Pasture

On This Page

FENCING SYSTEMS

WATERING SYSTEMS

Pasture infrastructure is an important component of grazing management. Various watering and fencing systems are covered in this module.

Fencing Systems

Key Points:

- The purpose of the fence, type of cattle, available labour, land topography and length of fence will determine whether barbed wire, hi-tensile electric or temporary fencing is the best solution for your grazing system.

- Fencing can be used to improve forage utilization and to protect sensitive areas.

- Fencing may need consider wildlife movement needs.

- Temporary fencing is generally used as interior fence to further divide pastures into smaller paddocks.

- Hi-tensile electric fence can be used in several situations, but requires an energizer and voltage monitoring:

- Energizer size is rated in joules. The higher the joule rating, the more intense the shock.

- Adequate voltage (minimum 2 kV) is required to carry electricity through the fence.

- Adequate grounding is important. Three ground rods per joule of energizer output capacity is generally considered ideal.

- 12.5 gauge hi-tensile wire is recommended as it conducts electricity very well.

- Polywire used for temporary fencing is a relatively poor conductor and is meant for short lengths of fence.

- Insulators must be used on steel posts and should be used on wood posts.

- Use the Fence Planning and Budgeting worksheet in the Toolkit to help you plan your fencing system. A filled-out example of this worksheet is also provided in the Toolkit.

- What is the purpose of fencing?

-

Fencing is the primary tool at a producer’s disposal to manage the grazing habits of livestock. Strategic placement of fences can help improve animal distribution and encourage more uniform forage utilization. Paddock design, along with herd size, can influence the stocking density of certain areas within a paddock, like the watering area, which will have an impact on pasture health and species composition. By dividing pasture areas into smaller paddocks, cattle can be rotated between paddocks to ensure that all forages are grazed and rested at appropriate times. Riparian areas and other surface water sources can be excluded from the grazing area with fence to maintain water quality, as well as herd and riparian health.

- What type of fencing should I use?

-

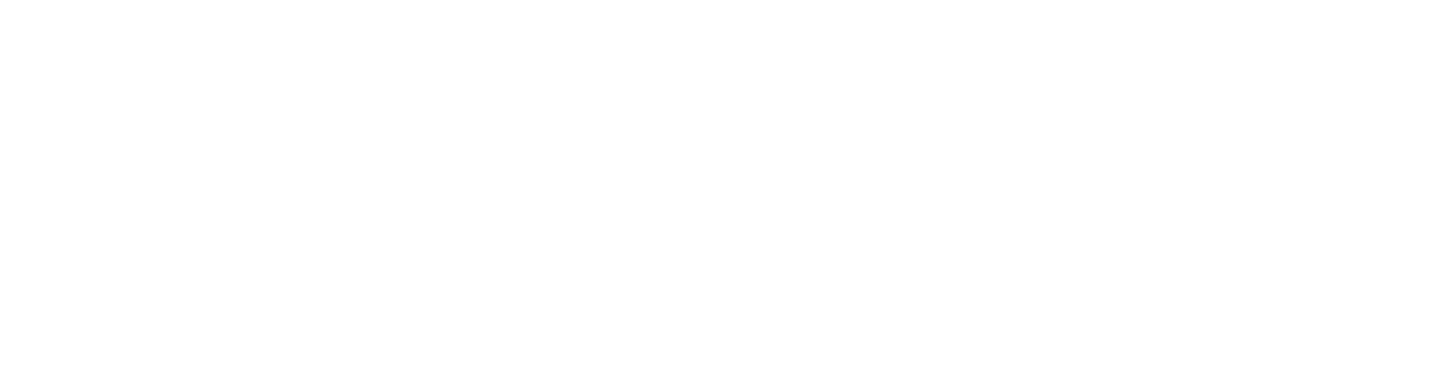

There are many options when deciding what type of fencing system best suits your grazing system. Permanent barbed wire fence is reliable and does not require an energizer but can be expensive to install.

Cattle should be trained to respect electric fence before they are turned out into a larger pasture with this type of fencing. Electric fence is more of a psychological barrier for cattle, while barbed wire provides more of a physical barrier. Training is not difficult and only takes a couple of days. In a relatively small pasture or corral, set up a temporary electric fence a few feet inside of a permanent fence on at least one side. Use a high-powered energizer for training. Cattle will ‘test’ this temporary fence and learn that they will receive a shock when they touch the wire. If the cattle do happen to go through the temporary fence during the training phase, they will still be contained by the permanent corral fence. Training is complete when the cattle understand and respect the temporary fence and have stopped ‘testing’ it.

Hi-tensile electric fence is less expensive to install and maintain than barbed wire fence but requires an energizer and frequent monitoring for drops in voltage. Hi-tensile electric fence provides more flexibility as it can be designed as a permanent fence with multiple wires, or a semi-permanent, single wire fence that can quickly be removed at the end of the grazing season. This makes it a good solution for rotational grazing on perennial pasture and annual grazing of cropland. Single wire fences also have the added flexibility of being able to create a gate at any point along the fence by lifting the wire and allowing the cattle to pass beneath it.

Temporary electric fencing is usually used as interior fencing to sub-divide paddocks. There are many options for wire and posts when it comes to temporary fencing. It is important to choose a product that has adequate conductivity for the length of fence you are constructing and is robust enough for the topography and type of cattle being fenced. For example, to contain cows and young calves, an electric fence will need at least two wires at varying heights. Choosing wire and posts that are easy to install and remove is important and will lessen labour costs associated with the frequent moves when using temporary electric fence.

It is common for a combination of all these fencing systems to be used on a farm or ranch depending on the topography, age of fence, length of fence, season of use, flexibility required, and type of livestock being contained.

- Considerations for electric fencing

-

How does electric fencing work?

For an animal to receive a shock, it must complete a circuit. When an animal touches a live wire, it completes the circuit between the live wire and the grounding system. The energy travels through the live wire to the animal and then through the soil to the ground rods and back to the energizer. This creates the shock.

What size of energizer is needed?

Energizer size is measured in joules. Think of joules as the amount of water in a pipeline and voltage as the water pressure needed to move that water down the pipeline. A higher joule rating will provide a more intense ‘shock’ when an animal touches it, but adequate voltage (minimum 2.0 kV) is required to carry that electricity down the wire.

Energizer size is measured in joules. Think of joules as the amount of water in a pipeline and voltage as the water pressure needed to move that water down the pipeline. A higher joule rating will provide a more intense ‘shock’ when an animal touches it, but adequate voltage (minimum 2.0 kV) is required to carry that electricity down the wire.

There are solar, battery and plug in models of energizers on the market. A plug-in energizer is the most reliable source of power, requires the least amount of maintenance, and can support larger energizers, but may not be practical in many situations. If using a solar and/or battery model, the panel or battery size must match the fencer output. When a battery powered model is used without a solar panel, the battery must be recharged on a regular basis to maintain an adequately powered fence.

Why are ground rods important?

An energizer is only as effective as its grounding field. Sufficient grounding is crucial to an effective electric fence system. As a rule of thumb, there should be a minimum of three ground rods per joule of energizer output capacity. Galvanized six- to eight-foot rods connected by a continuous 12.5 gauge galvanized wire is the most commonly used material for grounding systems. Ground rods should be driven deep into the ground to a level where the soil is moist year-round and placed a minimum distance of ten feet apart. Putting grounding rods in low, wet areas is more effective than dry, sandy or rocky areas.

How do you know if your grounding system is effective?

Testing a grounding system is straight forward but should be done during the driest part of the year:

- Short out the live wire by leaning metal posts or similar material against the live wire, connecting it to the ground. Place these posts approximately 300 feet from the ground rods. Use enough posts to draw the voltage in the live wire below 1.0 kV.

- Use a voltmeter to measure the voltage in the ground rod furthest from the fencer.

- A reading of over 0.3 kV can mean that:

- There are an insufficient number of ground rods (most common).

- The ground rods are too close together.

- The connection between the connecting wire and ground rods is poor.

What if effective grounding is not possible?

In very dry conditions, poor soil conditions, or on frozen ground, it is more difficult to establish an effective grounding field. An alternative to a traditional grounding system is an earth-return fence system. This is achieved by having alternating electrically charged and non-charged wires. The non-charged wire(s) act as part of the grounding system. The charged wires lead back to the energizer and the non-charged wires lead back to the ground or earth terminal. Alternatively, the non-charged wire can be connected to ground rods. An animal must touch both a charged and a non-charged wire to receive a shock.

What type of electric wire should be used?

The most used wire in an electric fencing system is 12.5 gauge hi-tensile wire due to the strength of the wire, its highly conductive nature, and because it doesn’t rust. Lighter wire, such as 14 or 16 gauge, is easier to work with, but has a higher resistance to current flow and should only be used for shorter lengths of fence. Think of the size of the wire like the size of a water pipe. The larger the pipe, the more water it can carry. The larger 12.5 gauge wire can carry the current a longer distance than smaller wire. Even if the fence is connected to a large energizer, if it is constructed with small wire the current will not be maintained at a high enough strength over a long distance due to the resistance in the wire.

Polywire is a type of wire made of a combination of conductive filaments interwoven with polyethylene, polypropylene or polyester fibres. Polywire is used primarily for short, interior, temporary fence such as strip grazing or dividing paddocks. Polywire is less conductive than high tensile wire and should only be used for short stretches of fence. The more strands of conductive filaments, the higher the conductivity of the wire. However, polywire with more strands is more expensive and will be bulkier, meaning less will fit on a reel. The colour of polywire is also important as visibility is key to keeping animals contained. For example, white polywire is the most visible on summer pasture in most lighting conditions.

What type of posts should be used for electric fencing?

There are many types of posts available for electric fencing made from wood, steel, fibreglass and plastic. Wood, fibreglass and steel posts of larger diameter are used for permanent hi-tensile fence. Insulators must be used with steel posts and should be used for wood posts to prevent the electricity from grounding out.

There are many different designs for posts for temporary electric fencing. Steel posts such as T-bar and rebar posts are durable, but heavy, and can be difficult to move and install. Plastic tread-in posts are the most convenient to use but are the least durable type of post. Consider how often the fence will be moved, how soft the ground is and the length of the fence when deciding on what type of post material is best.

- Planning a pasture system

-

When deciding on where to install fences and watering systems, it is important to consider the entire pasture system and grazing plan. There are many fencing options when it comes to implementing a rotational grazing system and dividing pastures into multiple paddocks.

A few of the most common paddock designs can be found, along with more information on pasture system design, in the Managing & Planning Grazing module.

Watering Systems

Key Points:

- Direct access to waterbodies has negative impacts on water quality, as well as cattle, wildlife, and riparian health.

- Off-site watering systems that offer clean water increase cattle productivity and weight gain but requires frequent and potentially daily monitoring.

- Larger pastures where cattle travel a longer distance to water will require a higher capacity watering system as cattle tend to water in larger groups.

- To achieve more uniform pasture utilization in high density grazing systems, the ideal distance to water is about 800 feet. In more extensive rangeland systems, typical advice is that cattle should not have to travel farther than about two miles on flat land and no more than one mile on rugged terrain to water.

- Pasture pipeline systems allow for watering throughout a pasture instead of cattle traveling to a central watering system.

- Both ground and surface water sources can be used for off-site watering systems, but ground water sources are the most reliable as long as they are accessible.

- Electricity is the most reliable power source. If using an alternative power source, it is important to have a backup plan in case there is a malfunction in the off-site watering system.

- Off-site watering systems can be used during the winter, but adaptations to the system and frequent monitoring are necessary to prevent freezing.

- Use the Water Systems Planning worksheet in the Toolkit to help you plan your watering system

- What impact do cattle have on water bodies where they have free

or direct access? -

Riparian areas are the lands located adjacent to bodies of water such as lakes, streams, rivers, and wetlands.

Cattle can destabilize the bank of water bodies, accelerate erosion, damage vegetation and the nests of grassland birds, reduce the lifespan of the water body, and reduce water quality. When cattle have direct access to water bodies, they will defecate in and around the edges of the water. This can increase the growth of algae , introduce harmful bacteria, and decrease the palatability of the water. Cattle that have direct access to surface water may experience higher rates of foot rot. When possible, fence cattle out of water bodies. If fencing off riparian areas is not feasible, setting up an alternate off-site water source can be effective in limiting the amount of direct pressure on the surface water source as cattle often choose the more accessible and higher quality water in the trough.

- What are off-site watering systems?

-

Off-site or remote watering generally refers to a system that prevents cattle from directly accessing a body of water. Several methods may be used to provide off-site water to cattle.

What benefits do off-site watering systems offer? Fencing off water sources and pumping water into a trough improves water quality and reduces water losses. Watering systems that offer clean water increase water consumption and have many benefits including:

- Increased weight gain.

- Improved herd health and reproductive performance.

- Safer watering sites, where cattle cannot fall through ice, get stuck in mud, and the water quality will not impact cattle health.

- Longevity of the water source.

- Enhanced wildlife habitat.

- Improved riparian health.

- Reduced erosion.

- Improved pasture utilization.

Excerpt adapted from the Beef Cattle Research Council Water Systems for Beef Cattle webpage.

To learn more, visit the Managing & Planning Grazing module.

For more information on the impact of water quality on herd health and production visit the Grazing-Related Animal Health Concerns module.

- What off-site watering system should I consider?

-

There are a wide variety of off-site watering systems to choose from and the system best suited to your pasture will depend on the resources available, the management system and your herd. Permanent or portable watering systems can be combined with different power sources, trough set ups, pump models and water sources to fit each pasture.

Livestock Watering Systems in Saskatchewan: Producer Experiences details examples of a variety of watering systems used by producers.

When choosing a watering system there are many factors that should be considered including:

- Grazing management system.

- Herd size and animal type (yearlings, cow/calf, bulls, dry cows).

- Site characteristics and availability of water sources.

- Season of use.

- Proximity to electricity or alternate power source.

- Cost to install, maintain, and operate.

- Labour and time to check the system.

- Desired proximity of water system to forage.

- Desired ability to change the watering system during the grazing season or from year to year.

- Does the location of the watering system affect pasture utilization and watering capacity?

-

The location of the watering system will affect the required watering capacity. The larger the pasture and the farther the cattle have to travel to reach the watering system, the more likely the herd will travel as a group to water instead of as individuals or small groups. This means a higher capacity trough and watering system will be needed to provide water to all the animals when they arrive to drink.

The location of the watering system will also impact pasture utilization. When cattle have to travel further to water, they spend more time walking back and forth as well as in the watering area. This can cause the forage nearest water to be overutilized, while the forage furthest away may be underutilized. In high density grazing situations, the most even pasture utilization may be achieved when cattle do not have to travel farther than about 800 feet to water. Under more extensive rangeland systems, typically utilization becomes more uneven when cattle have to travel further than two miles on flat land or more than one mile on more rugged terrain to water. If improving pasture utilization is a goal, new water sources can be developed to reduce the distance cattle travel to water, water can be hauled to portable watering systems, or a pasture pipeline system can be established.

Pasture pipeline systems are typically built with small diameter polyethylene pipes that are buried 6-12 inches below the soil surface connected to a series of risers to supply water at multiple points within the pasture. These pressurized systems are seasonal, and the pipes will need to be blown out with air in the fall, so they don’t freeze.

Alberta Agriculture and Forestry’s Pasture Pipeline Design fact sheet has more information on building a pasture pipeline system.

Water can be hauled to each paddock within a pasture instead of installing a pipeline system or developing a new water source. Hauling water to the cattle can be very labour intensive depending on the number of cattle and hauling capacity. Some producers have customized water trucks with add on troughs to provide fully portable water systems.

- Is it better to use ground water or surface water for off-site watering

systems? -

Both groundwater and surface water sources are compatible with a wide range of off-site watering systems. It is important to match the pumping system to the water source. This includes taking into consideration the amount of lift from the water source to the trough while maintaining adequate flow rates.

Drilled wells are a very reliable source of water since variations in precipitation will not change the available water supply. However, not all areas have good quality aquifers close enough to the surface to be able to drill a well. If an existing well does not exist, it can be expensive to drill a new well.

Surface water sources are more dependent on precipitation. If you are using a water source that is likely to be available for only part of the growing season, such as a seasonal stream or slough, it is important to adapt your grazing plan to graze these paddocks early in the year or be prepared to haul water if you want to utilize this forage later in the season. During prolonged periods of drought, smaller dugouts and streams can be at risk of drying up. In these instances, a plan for alternative water sources should be in place.

Stagnant surface water sources, especially in drought conditions, can have water quality issues. As water quality can change from year to year, or even within a grazing season, testing your water is the best way to ensure that it will not pose a risk to your cattle.

For more information on water quality visit the Grazing-Related Animal Health Concerns module.

- What types of power sources can be used with off-site watering

systems? -

There are a variety of power sources that can be used in an off-site watering system. Many systems run on a combination of power sources. For example, a combination of solar panels and back-up batteries.

Electricity is the most reliable source of power. However, if the water source is not located close to existing electrical infrastructure it can be expensive to have power installed. Electric waterers are a reliable, long term water source that are suited to both summer and winter use.

Fossil fuel powered generators can be used to power watering systems but do need to be checked frequently. Portable pumps can be used to fill an elevated storage system that then uses gravity to flow to a trough on a valve and float system.

Gravity fed watering systems are an option if the existing landscape has the appropriate slope. This type of system relies on gravity to move the water from the initial source to the water trough. This will only work if you have a water source that is uphill. These systems are relatively low cost and low maintenance.

Solar panels can be used to power a variety of watering systems. Panel size will need to be adjusted to suit the water consumption of the herd and the amount of lift required from the water source to the trough. Panels can be paired with a back-up power source such as a battery for extra reliability during cloudy periods. Solar panels are portable, so they can be used at multiple watering sites throughout the grazing season.

Windmills use the rotary motion of the propeller to power the watering system. Windmills can also be used to aerate a dugout, which can improve water quality. Even at the windiest sites, wind speeds will still be variable and a back up power source is generally required.

Batteries are often used as energy storage for a back-up power source in combination with another power source such as solar panels. Remember to match the type of battery to the temperature conditions.

Sling pumps can be used to power a watering system where a flowing water body such as a creek, river, or stream is available. The stream needs to flow at a minimum velocity of 60 centimetres/second (2 feet/second) and have a minimum depth of 25-40 centimetres (10-16 inches). Since a sling pump runs continuously it is important to have an overflow hose to discharge excess water away from the trough (perhaps back into the flowing water body) where animals congregate.

Nose pumps rely on the cattle to power the watering system. Cattle can learn to push and release the lever to operate the pump. Nose pumps should only be used where the lift from the water source to the basin is less than 20 feet. Nose pumps only water one animal at one time, but multiple nose pumps can be set up at the same watering site to accommodate more animals. Small calves may not be strong enough to operate the nose pump so an alternative water source should be available for young calves.

- What should the watering capacity be?

-

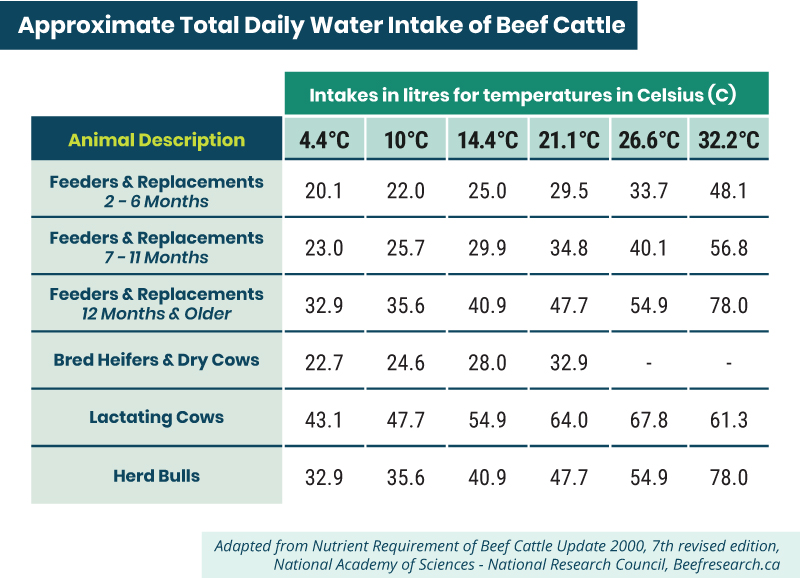

Grazing systems impact the water capacity requirements of the watering system. When water sources are centralized in large pastures, cattle tend to move as a herd, including when they water. In these situations, a watering system should be able to accommodate the entire herd in roughly 20 minutes to reduce competition. Use the water intake table below to help you calculate the water requirements of the class of cattle you plan to water in a specific location. If the watering system does not have sufficient capacity or water flow, younger, thinner, or less dominant animals may not have a chance to drink enough before the herd moves on to grazing in another part of the pasture.

When pastures are smaller and animals travel shorter distances to water, they tend to drink either individually or in small groups, reducing the strain on the watering system. In pasture systems like this, smaller troughs can be used if the water flow can maintain the trough water level while cattle are drinking.

- What happens if the watering system fails?

-

It is important to have a back up plan for every off-site watering system. Every system has vulnerabilities from float malfunctions to power issues. Cattle cannot be without a water source for very long, especially in the summer months, so a “Plan B” is important. This can be as simple as allowing direct access to a water source temporarily or moving cattle to another pasture with a different watering system.

- Can off-site watering systems be used in the winter?

-

Allowing cattle direct access to surface water in the winter increases the risk of cattle breaking through the ice and drowning. Using electricity as a power source is the most reliable and the most versatile for off-site watering during the winter. A variety of permanent, heated watering bowls powered by electricity are available. Other systems utilize different heat sources, such as geothermal heat or floating tank heaters. Power sources besides electricity can also be used but will likely require extra attention in the winter months. For example, if using solar panels during the winter, adequate battery storage and an alternative back-up power source is a good idea because the winter months have fewer hours of sunlight. To help to avoid water freezing in the trough, off-site winter watering systems typically use a drain back, continuous flow or insulated trough system.

Use the Water Systems Planning worksheet and the Fence Planning and Budgeting worksheet in the Toolkit to help you plan your fencing and watering systems.

Test Your Knowledge

Information adapted from

- Water Systems for Beef Cattle

Beef Cattle Research Council webpage - Pasture Pipeline Design

Alberta Agriculture and Forestry PDF - Riparian Areas and Grazing Management

Cows and Fish PDF - Remote Pasture Water Systems for Livestock

Alberta Agriculture and Forestry PDF - Remote Winter Watering Systems for Beef Cattle

Manitoba Agriculture and Resource Development PDF - Beef Cattle Handbook: Fence Systems for Grazing Management

University of Missouri Extension Beef Cattle Resource Committee PDF - Energizers and Energy

Gallagher Group Limited PDF - Temporary Fencing for Rotational Grazing

University of Tennessee PDF - Grounding Electric Fences

University of California Cooperative Extension PDF

TOOLKIT

- Water Systems Planning Worksheet

- Fence Planning and Budgeting Worksheet

- Example Fence Planning and Budgeting Worksheet

Other Resources

- How quickly do water systems pay for themselves?

Beef Cattle Research Council calculator - Troughs for Watering Range Livestock

Agriculture and Agri-Food Canada PDF - Summer Livestock Watering Troughs

British Columbia Ministry of Agriculture, Food and Fisheries PDF - Livestock Watering Systems in Saskatchewan: Producer Experiences

Ducks Unlimited Canada PDF - Wire Fences for Livestock Management

Agriculture and Agri-Food Canada PDF - Fencing with Electricity

Alberta Agriculture and Forestry PDF